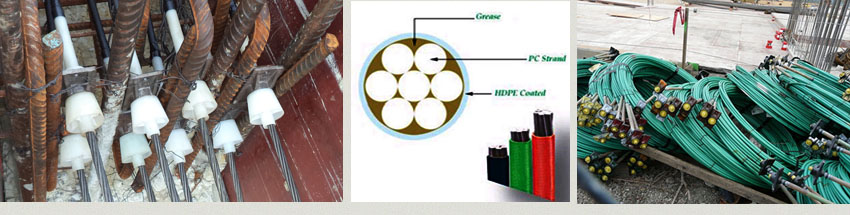

Bonded post-tensioned concrete is the descriptive term for a method of applying compression after pouring

concrete and during the curing process (in situ). The concrete is cast around a plastic, steel or

aluminium curved duct, to follow the area where otherwise tension would occur in the concrete

element.

A set of tendons are fished through the duct and the concrete is poured. Once the concrete has hardened,

the tendons are tensioned by hydraulic jacks that react (push) against the concrete member

itself.

When the tendons have stretched sufficiently, according to the design specifications (Hooke's law), they

are wedged in position and maintain tension after the jacks are removed, transferring pressure to the

concrete. The duct is then grouted to protect the tendons from corrosion.

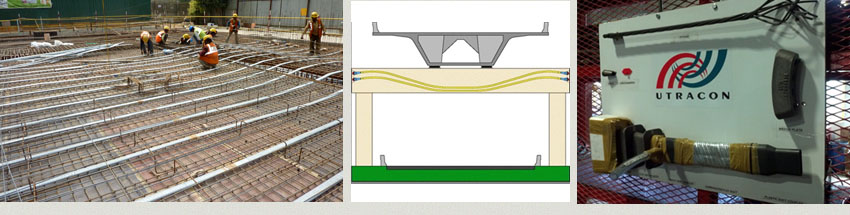

This method is commonly used to create monolithic slabs for house construction in locations where

expansive soils (sometimes called adobe clay) create problems for the typical perimeter foundation. All

stresses from seasonal expansion and contraction of the underlying soil are taken into the entire

tensioned slab, which supports the building without significant flexure.

Post-tensioning is also used in the construction of various bridges, both after concrete is cured after

support by false work and by the assembly of prefabricated sections, as in the segmental bridge.

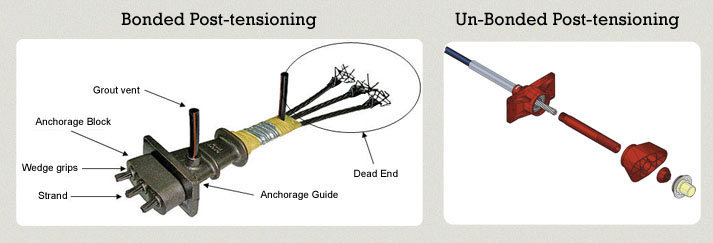

Among the advantages of this system over unbonded post-tensioning are:

* Large reduction in traditional reinforcement requirements as tendons cannot de-stress in

accidents.

* Tendons can be easily "woven" allowing a more efficient design approach.

* Higher ultimate strength due to bond generated between the strand and concrete.

* No long term issues with maintaining the integrity of the anchor/dead end.